Bronze Casting

All my sculptures can be cast in Bronze Metal. This is different from all the items called “Faux Bronze color” on the website. This is similar in process, as the figure needs to be cast from the molds I create. From that point, the figure has to be taken to a Bronze Foundry. The Bronze Foundry will then use the Lost Wax Process to finish the casting. It is a time involved process, so please understand that this is not a fast finished figure like the cold cast version. These castings may take as long as 4 months to complete depending on the work load at the foundry.

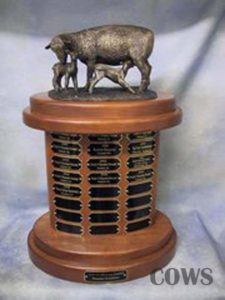

This is a portrait sculpture to be cast in Bronze metal

An Abbreviated discription of the Lost Wax process:

From the raw sculpture, a mold is made and the casting is poured in WAX. The WAX casting is then taken to the foundry. The wax is then dipped in Investment that creates a thick shell around the casting. Once hardened, the wax is them melted out of the shell, to leave the negative space to be filled back in with Molten Metal Bronze. This has to cool off, and then the investment is cleaned off the metal to expose the sculpture again. Once the investment is all cleaned off and out of all the details (very time consuming) the metal is then cleaned the piece is then ready for patina. The Bronze has to be reheated to accept the chemical patina. Once finished to the customers desired finish, the bronze in mounted on a Walnut base or Trophy base. These castings are quite heavy.